published on 21.04.22

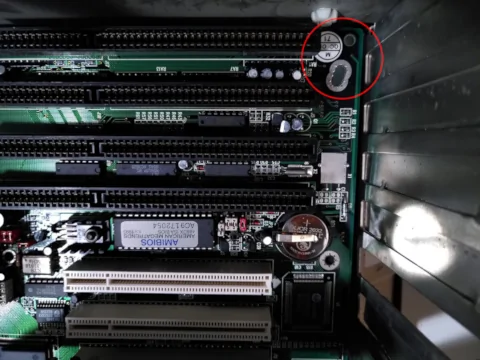

I’ve been asked to fix an old computer: this vintage desktop PC from around 1996 has a rather wobbly motherboard. I’ve restored the rest of the PC, but it’s going to need some creative thinking to fix the motherboard problem. It’s also going to need a drill! The PC has got a standard mini-ATX motherboard, in a standard Midi tower case. But, as per the photo above, some of the mounting holes on the motherboard don’t match the holes or slots on the case. In this situation, you can end up with a motherboard that’s only fixed in place with two or three supports. And that may not be enough. This was a thing back in the 90’s with early PCs that varied somewhat in specification: you generally had brass spacers to mount motherboards, and most cases had a number of mounting holes for them in various positions, and some even had slots for moveable plastic spacers. So far so good. But, the spacers didn’t always line up with the holes on the motherboard: you were lucky to be able to fully mount a motherboard properly, with spacers evenly distributed. Mostly you could get away with a missing spacer or two, but in some situations, you can end up with a wobbly motherboard, with no support in one corner, or along one side, and that can cause issues when you’re inserting an expansion card into a slot, or adding some extra RAM: the motherboard will actually bend and flex. And if it bends too much, you’ll break electrical tracks on the motherboard PCB, and then there can be major issues, which can be tricksy to diagnose and fix. The best thing is not to bend the motherboard at all.

Sometimes, to fix an old computer, there’s no easy solution:, you just need to get creative with a drill!

Mark up the position of the spacer hole you need on the case

then get a 2.5mm drill and a 3.0mm tap

drill the 2.5mm hole, then carefully tap with the 3.0mm tap.

finally, insert the brass spacer into the newly tapped hole.

Done!

make sure to clean up the metal swarf from drilling the hole properly – it’s really not good for electronics!